Sanctions pressure exerted by the international community produces a multi-layered, yet indirect, effect on the functioning of Russia’s military-industrial complex. This pressure drives the continuous transformation of production chains, the redistribution of investment capital, and shifts in the innovation dynamics across the entire structure of Russia’s defense-industrial sector.

The exposure of shadow servicing networks or the illegal updating of CNC machine software creates conditions for tighter international oversight, the initiation of new sanctions measures, audits of manufacturers, and the disruption of technological support channels for Russia’s military-industrial complex.

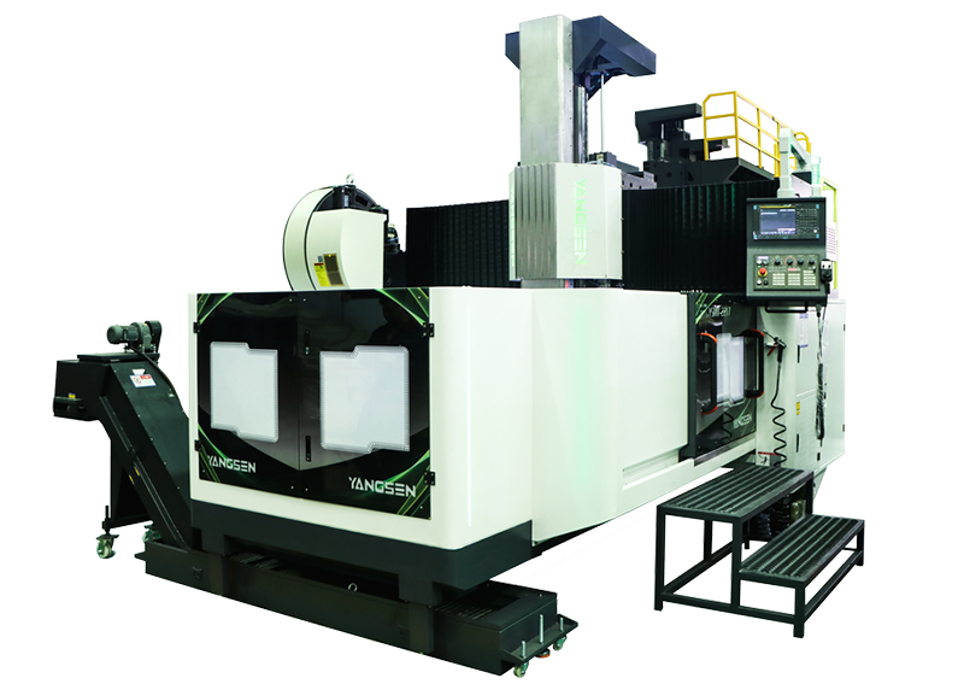

Despite sanctions pressure, companies integrated into Russia’s defense-industrial complex continue to operate high-tech machine tools of Western origin. Moreover, in several cases, enterprises that serve as critical nodes in the production chains of tactical and strategic weapons for the Russian Armed Forces—while sanctioned by Ukraine—remain outside the sanctions regimes of Western states.

At the Perm-based industrial complex IOLLA, modern German, Japanese, American, and other foreign machine tools remain in operation, including Schuler presses and CNC machines produced by DMG Mori, Haas, OKK, SEIBU, and others. These technologies are critical for manufacturing complex components and defense-related products. The absence of equivalent domestic alternatives in Russia forces the company to rely on grey-market import schemes and illegal servicing.

Why Have Russian Machine Tools Failed to Become an Alternative?

The IOLLA industrial group, headquartered in Perm, specializes in the production of low-power electric motors and cooling fans for electronic equipment. Manufacturing such complex products requires a fleet of high-precision foreign-made machine tools. Despite its deep integration into Russia’s defense-industrial complex, the company continues to service and update foreign equipment to which access should have been fully blocked under existing sanctions.

The company’s official website openly showcases an extensive inventory of foreign-made equipment, including:

- Schuler press equipment (Germany) – high-speed stamping presses used to produce stator and rotor laminations for electric motors. The facility operates an automatic Schuler Smartline SA-125S-1.8 press for rapid stamping of thin metal sheets, as well as several eccentric presses (CBL400a and CFL1000c). This equipment enables mass production of steel laminations with the geometry and precision required for electric motor cores.

- CNC machining centers – multi-axis machines for precision milling and turning. According to official disclosures, IOLLA operates a Haas Super MiniMill vertical machining center (USA), OKK VP9000 high-speed machining centers (Japan), a DMG Mori DMC 1150 V machining center (Germany–Japan), and a Fermat WFC 11 horizontal boring mill (Czech Republic). Turning operations are performed using Miyano ABX-54SYY multi-axis lathes (Japan) and Hyundai Wia LM1600TTSY machines (South Korea).

- Electrical discharge and grinding machines – used for machining especially hard materials and achieving high-precision finishes. The company operates a SEIBU M500SG wire-cut EDM machine (Japan) for producing complex metal contours with extreme accuracy, as well as Ziersch ZT 48 and ZT 612 surface grinders (Germany), which ensure mirror-level smoothness for dies and molds.

German and Japanese machine tools, along with American CNC systems, constitute critical infrastructure for IOLLA. It is precisely this equipment that enables the production of precision components for electric motors and other technical systems.

Technological Dependency

The production of stators and rotors requires micron-level precision, stability under high loads, and high-speed operation—parameters that no Russian manufacturer is currently able to meet. As a result, foreign machine tools represent a technological dependency that Russia has been unable to overcome.

Machines produced by Schuler, DMG Mori, and Haas require:

- regular calibration,

- replacement of components,

- firmware updates,

- software license renewals,

- service diagnostics,

- manufacturer technical support.

Without these, precision degrades—and with it, the ability to fulfill defense contracts.

Foreign machine tools thus constitute the foundation of Russia’s industrial capacity. Russian factories deprived of access to such equipment rapidly lose competitiveness. The UK-based RUSI has noted, for example, that Russia’s production of artillery barrels is “100% dependent” on Austrian GFM forging machines—equipment Russia cannot manufacture domestically. A similar situation exists in the high-precision metalworking sector.

Even Russian officials have acknowledged that the country remains unable to substitute critical machine tools and continues to rely on foreign supplies. Without DMG Mori or Schuler equipment, entire categories of production—from electric motors to artillery systems—would cease. Western technologies are therefore effectively irreplaceable for Russia’s defense-industrial complex.

Sanctions Evasion Schemes

International sanctions were intended to sever Russian factories from Western equipment and servicing. In practice, however, Russia’s defense-industrial complex has adapted to circumvent many of these restrictions. The toolkit includes parallel imports via third countries, shadow transit of spare parts, use of legacy inventories, and computer-engineering solutions to keep machines operational.

High-precision machine tools require regular maintenance, including replacement of cutting tools, electronic components, and scheduled repairs. Official representatives of DMG Mori, Haas, and other manufacturers announced the suspension of operations in Russia after sanctions were imposed. DMG Mori, for example, declared in February 2022 that it would halt sales and service and shut down its plant in Ulyanovsk.

Yet evidence suggests that unofficial support continued. In July 2023, the Moscow Arbitration Court issued ruling No. A40-51758/23-62-407 concerning the supply of machine components by a Russian subsidiary of DMG Mori to an aircraft-engine defense plant as late as August 2022. Even after formally exiting the market, company personnel and warehouses continued to supply spare parts.

Such operations are likely disguised as sales of remaining inventory or transfers of rights to third-party firms that resell components under their own branding. For enterprises like IOLLA, access to original spare parts is vital—without them, maintaining machine operability becomes nearly impossible.

Where official channels are closed, grey-market service companies step in. A shadow servicing sector has emerged in Russia, where former engineers from Western company offices continue to maintain machines at their own risk, using illegally imported parts or dismantling older machines for components—a phenomenon known as “equipment cannibalization.

Software and Digital Workarounds

Modern CNC machines rely on complex software systems requiring periodic updates. Manufacturers can remotely monitor machine status; Haas, for instance, introduced online telemetry systems that transmit operational data to service centers. For Russian users, this became a liability: telemetry can reveal machine location, enabling manufacturers to deny support or disable software.

According to available information, Haas Automation halted software updates for Russian clients and terminated agreements with its Russian dealer early in the war. In response, companies like IOLLA disconnect machines from the internet and rely on outdated software versions. Local control systems are configured to prevent data transmission and avoid detection.

To maintain operability, Russia’s defense-industrial complex employs computer engineers to bypass technical restrictions and stabilize Western machines. Despite sanctions, machines remain operational by being shifted into autonomous mode and maintained domestically to the extent possible.

Undermining Sanctions Effectiveness

These practices significantly undermine the sanctions regime. Although direct deliveries of machines to Russia are formally halted, new equipment continues to appear on factory floors, and existing machines receive spare parts. This directly weakens the effectiveness of sanctions: if weapons production continues uninterrupted, the strategic goal of degrading Russia’s military capacity is only partially achieved.

Strengthening Control and Manufacturer Accountability

The exposure of widespread sanctions-evasion practices has created momentum for stronger enforcement mechanisms. Journalistic investigations and expert analysis point to several priority measures:

• Manufacturer audits and liability

Western machine tool manufacturers should be required to audit their distribution networks and end users thoroughly. A “No Russia” compliance marker should apply equally to parent companies and their subsidiaries in third countries. If a European manufacturer operates facilities in China or Turkey, those entities must also be legally bound by sanctions. Proven violations should trigger investigations and, if necessary, sanctions against the manufacturers themselves. Parent companies must be held accountable for their subsidiaries’ actions.

• Stricter supply-chain control

A multinational tracking system should be established for high-precision machine tools and key components (CNC modules, laser heads, etc.). Manufacturers must regularly monitor end users, collect buyer data from distributors, and conduct spot inspections. Intermediary firms facilitating imports to Russia should be rapidly sanctioned.

• Technical countermeasures

More radical measures are under discussion, including remote shutdown capabilities for machines used in sanctioned jurisdictions. While legally and ethically complex, preventive measures—such as GPS modules or software “time bombs” requiring periodic license verification—may become standard if traditional controls fail.

• International coordination

Sanctions-coalition countries are strengthening information sharing on evasion attempts through joint working groups, particularly within the G7. Exporters are being issued guidance on identifying suspicious orders, vetting buyers, and enforcing no-reexport clauses. Germany has launched audits of machine-tool manufacturers’ post-2022 deliveries, with violators facing heavy fines and exclusion from public procurement.

Conclusion

The case of the Perm-based company IOLLA demonstrates that Russian defense enterprises involved in state defense procurement continue to benefit from globalized technology markets. Western machine tools once sold to Russia have become a frontline of confrontation—still machining components for Russian missiles and tanks despite sanctions.

This highlights a critical vulnerability in the sanctions regime: unless evasion channels are closed, sanctions pressure dissipates and fails to achieve its intended effect. A proactive approach—combining sanctions with technological controls and close cooperation with industry—is essential.

In the long term, technological isolation of sanctions-evading companies will intensify. The international community increasingly recognizes that every illegally imported machine tool translates into missiles or drones potentially used in war in Europe, including the Baltic region.

Equipment directly enables Russia’s military capability

Schuler and DMG Mori machines are used to manufacture:

stator and rotor packs for electric motors employed in: armored vehicles, unmanned aerial systems, high-precision instruments; dies and molds for mass metalworking; high-precision components for missile, aviation, and mechanical systems.

More on this story: Chinese Components for Russian Fiber-Optic Drones

More on this story: Russia Under Sanctions: Diversifying Trade Routes to the East

More on this story: Kazakhstan’s Expanding Role in Russia’s Sanctions-Evasion Architecture

More on this story: Russia Circumvents Sanctions Through Chinese Marketplaces